- Published on

- Summer 2021

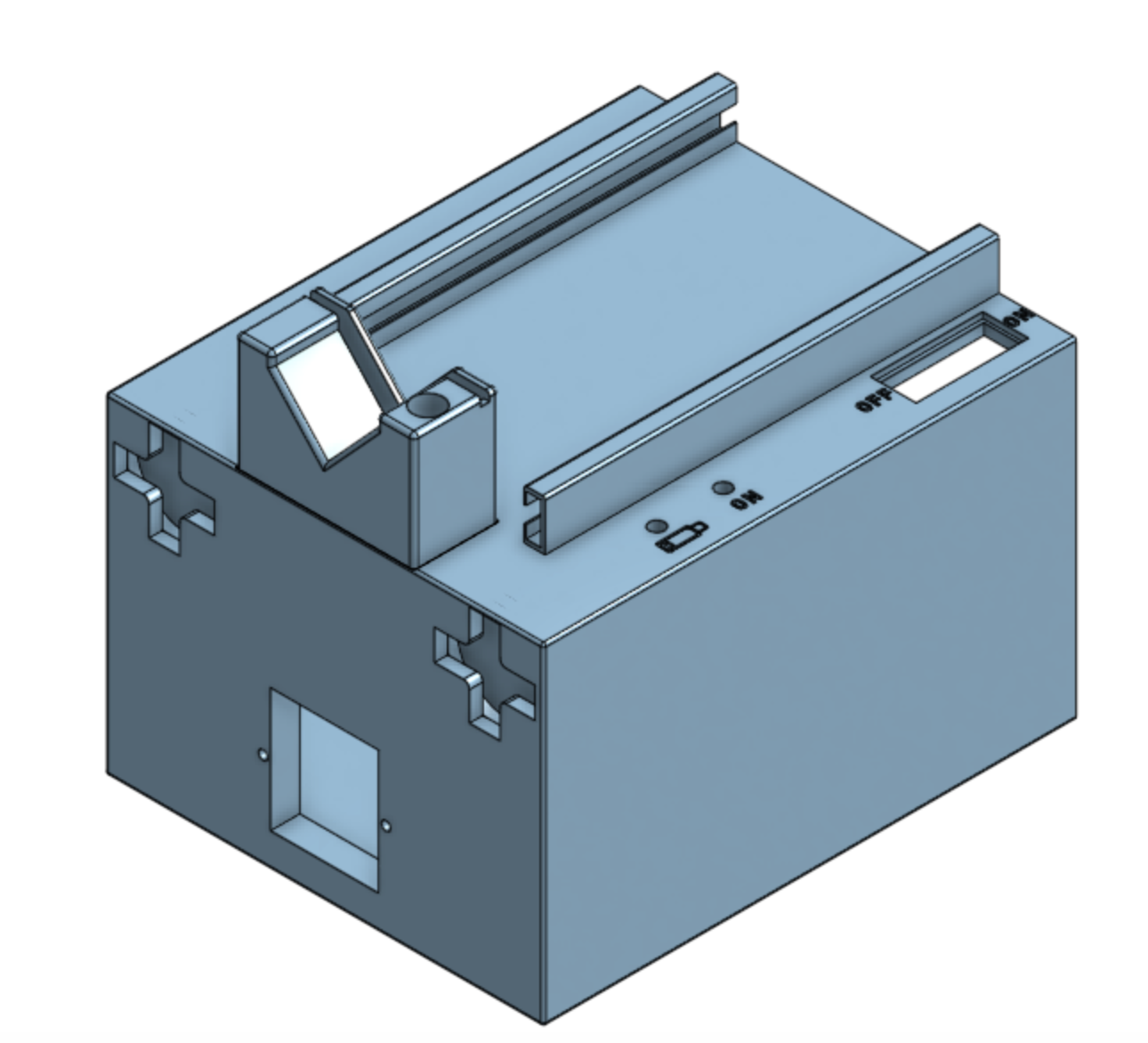

Ergonomic Syringe Pump

A liquid injection and withdrawal device suitable for multiple syringe sizes to reduce strain on pharmacists' hands

Role

Engineering Lead

Skills Used

- CAD in OnShape

- Circuitry

- PCB design in KiCad

Collaborators

Brian Bosem

Background

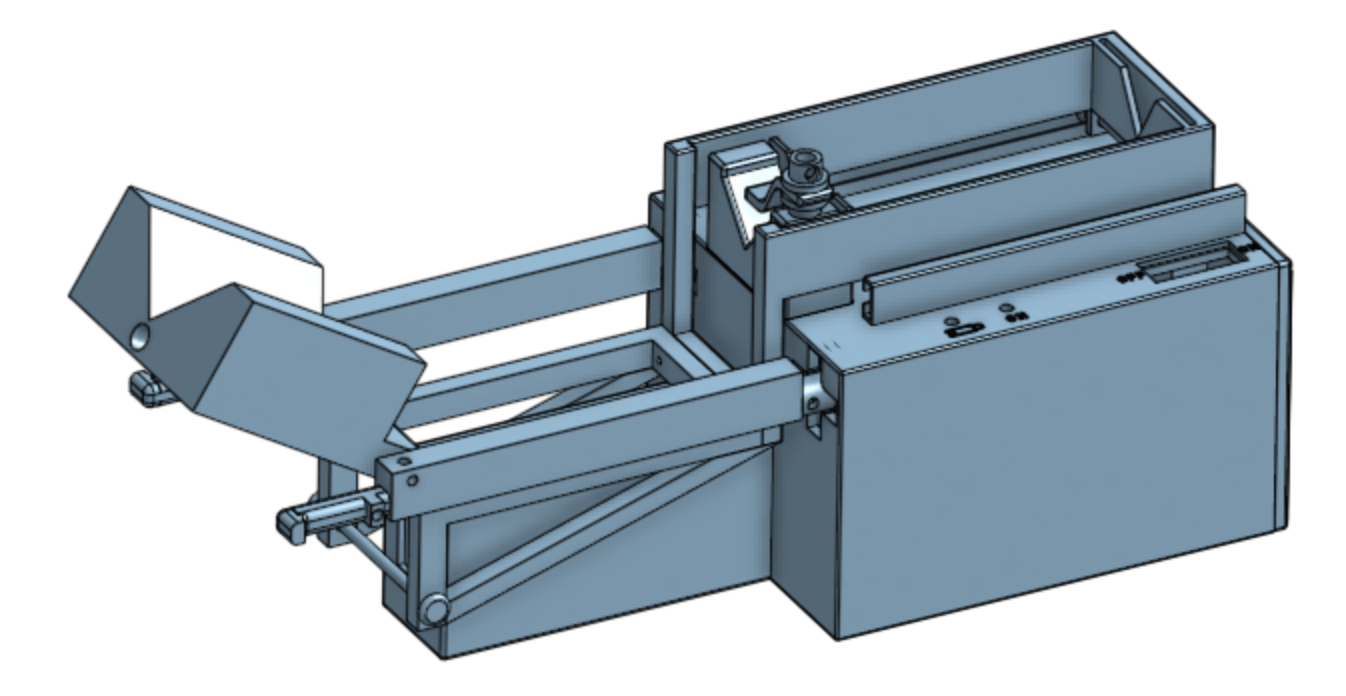

Technicians at the Duke Pharmacy have difficulty injecting and withdrawing liquids with 30 and 60 mL syringes. It requires concentrated, steady, two-handed movements by the technicians and places undue strain on their wrists. We were tasked with creating a device to mitigate technician strain when using syringes of all sizes for both bottles and IV bags at several different angles, including horizontally, vertically, 30, 45, 60, and 90 degree angles. We ultimately created an ergonomic, cost-effective syringe pump. Special consideration was given to ease of device sterilization, bottle placement in order to allow for adequate air flow when the device is placed in a lavendar flow hood, and size of the device so it can be stored in a cabinet or in the back of a flow hood.

Key Features

- A syringe pump driven by a Bluetooth remote-controlled linear actuator

- A versatile clamp for all syringe sizes

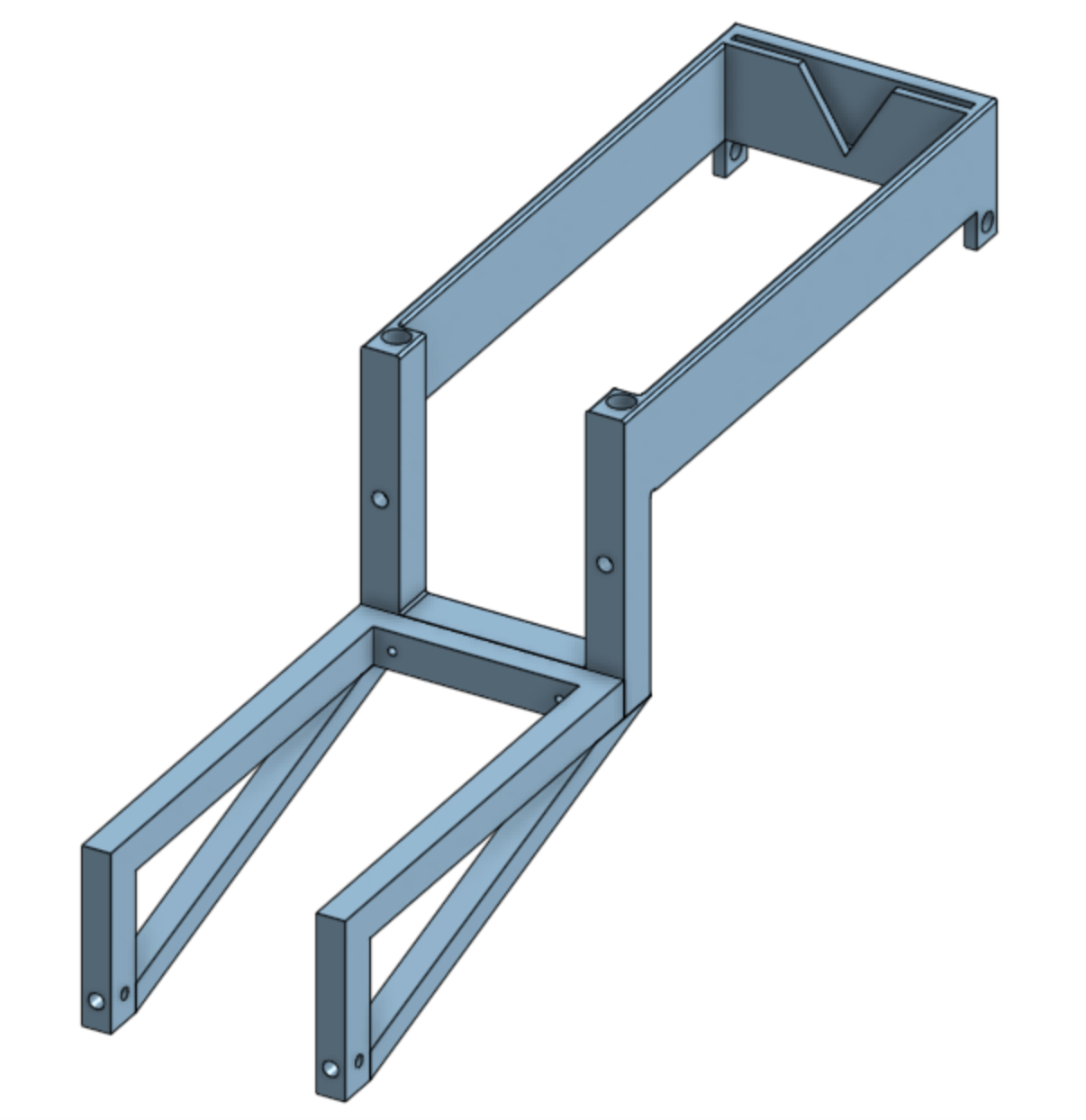

- A detachable bottle and IV bag holder

- An on/off switch and LED power indicator

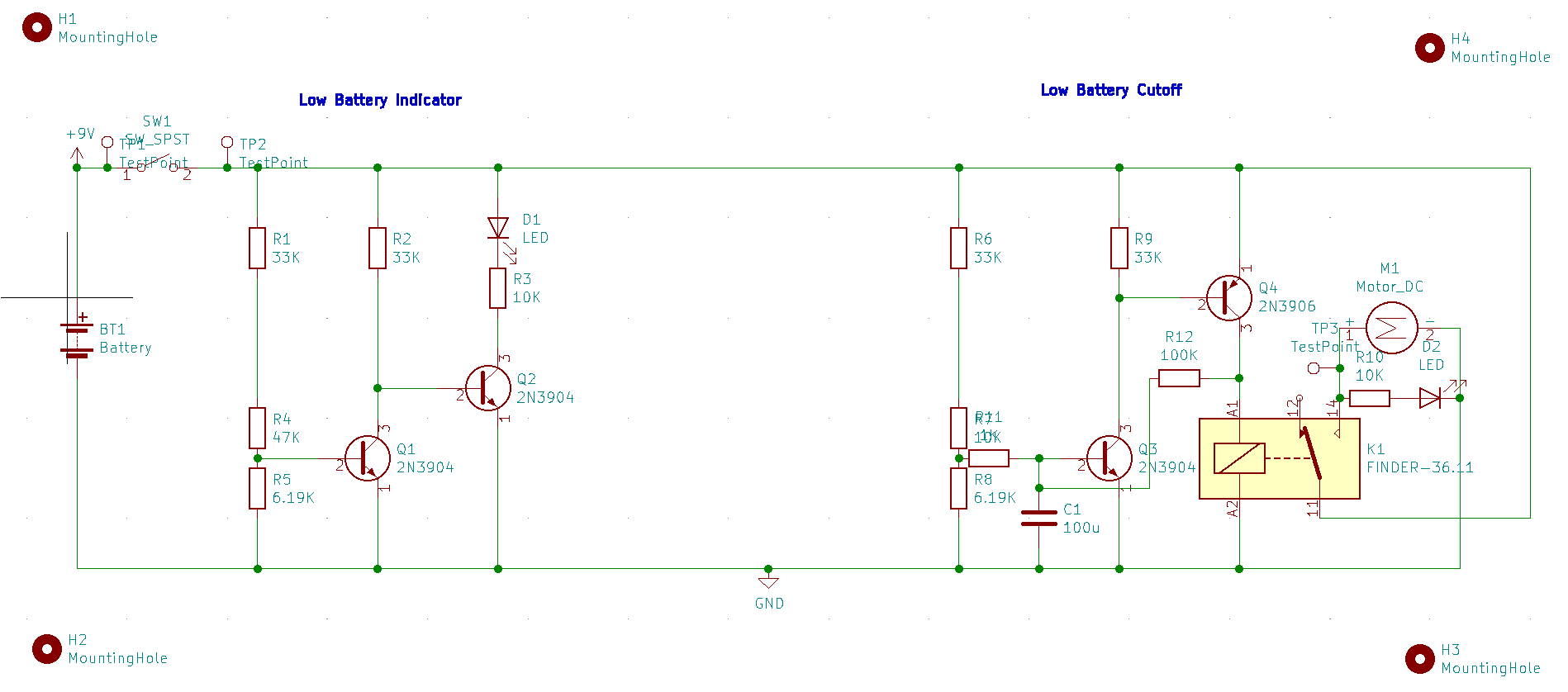

- A low battery LED indicator and cutoff protector

- An easily replaceable battery with a life of > 15 hours

- 7 different angles of use

- An affordable and easily sterilized enclosure

Final Design

Product in Use

Low Battery Replacement

Device On

Low Battery

Device On, Low Battery

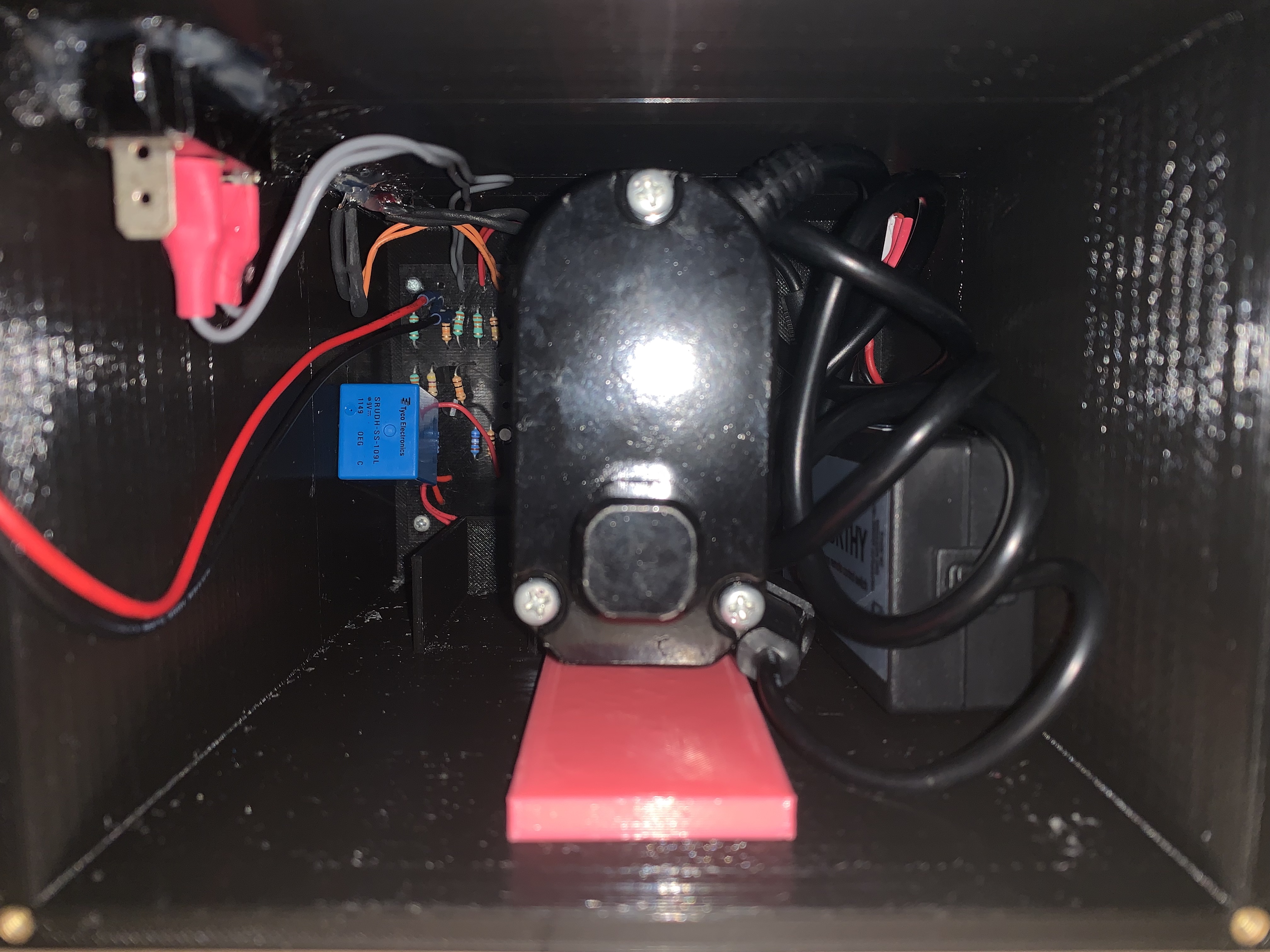

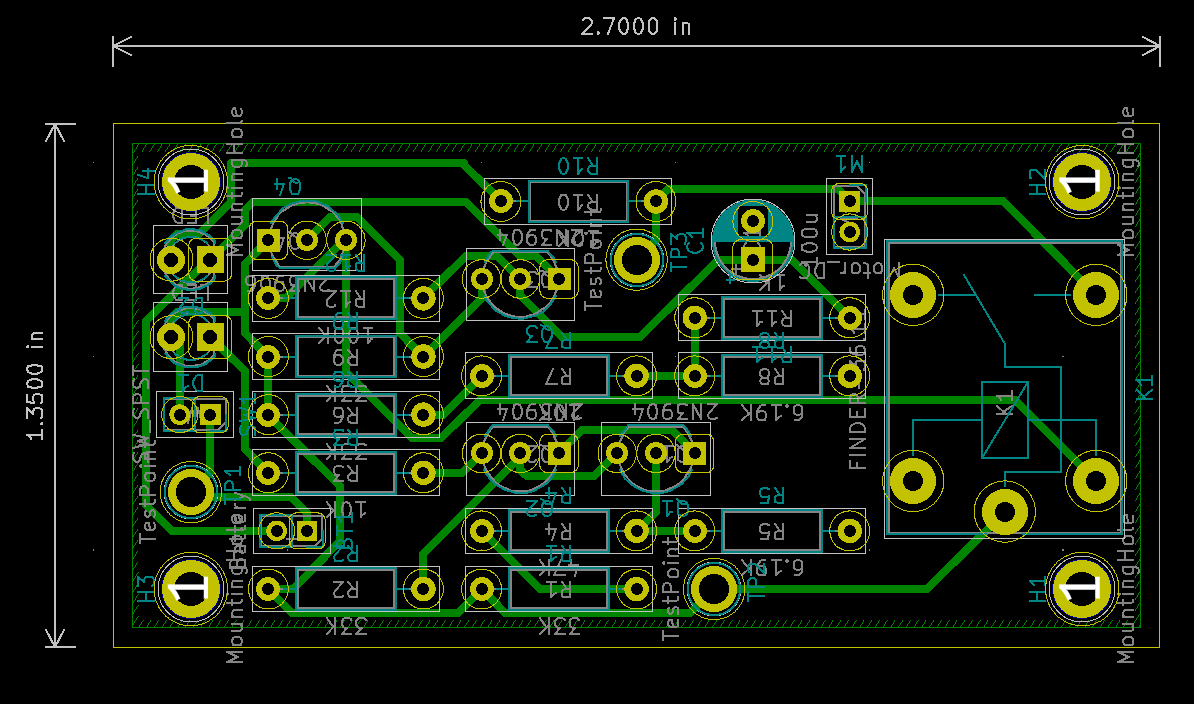

Electronics Design

Replacing Syringe

Bottle Holder

CAD Design

Reflection

Throughout the design process, we regularly communicated with the Director of Ergonomics at the Duke University Healthcare System, Marissa Pentico. By the end of the summer, she told us that this device was a great first step in creating a more ergonomic environment for Duke Pharmacy technicians. We met each of the user needs, including reducing strain on pharmacists' hands, functionality for all customary syringe sizes, the ability to attach and detach a bottle holder, compact size, the ability to work at multiple angles, a long battery life, a low cost, and minimal surfaces to increase ease of sterilizing. Additionally, there are several potential of improvement, including creating a more ergonomic attachment system for the bottle holder, waterproofing the device, and creating a user interface that allows pharmacists to change the speed of the linear actuator. We are in the process of filing an Invention Disclosure Form, and this project will ultimately be passed on to students who will build from our work in a future semester.